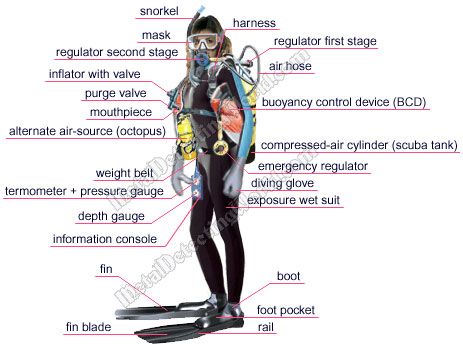

A buoyancy control device includes an input means for a second rate of ascent. You may select the second rate by using the input means 81. This may also be known as a rate selection button. The second rate may also be selected by ignoring the first one. Depending on the circumstances, a buoyancy control device may be comprised of a number of different features. The buoyancy control device may include a buoyancy pump and a weight belt.

Weight belts

The centre of buoyancy for a diver is not within his control. However the suit's weight, and the position in the cylinder, are within his reach. Weight belts and integrated BC weighs are also options that divers can use to control their buoyancy. These buoyancy control devices can be worn at the waist, above your hips, and below your knees to give you a neutral trim.

Dump valves

A BCD has two separate ways to control your buoyancy. You can either deflate the air bladder completely or you can add air to freshen the bladder. Dump valves can be attached to a string to regulate the level of air. BCDs typically have one to two dump vales on each shoulder. To maintain comfortable buoyancy while diving, the dump valves allow you to inflate the air bladder.

Jacket-style buoyancy control device

You can invest in a jacket-style BCD, whether you're new to diving or have been diving since years. Many BCDs can be worn over a swimsuit so that the weight stays in place. Some models come with front weight pockets and rear trim pockets for easy access to your weights. A jacket-style BCD is equipped with a cushioned, hard back. It makes wearing it comfortable and allows for easy adjustment of its buoyancy gauges.

Attachment systems in BC

A BC is a type scuba dive vest used by divers to maintain buoyancy and prevent sinking. A BC is designed to hold the diver and SCUBA tank securely in place. BCDs can be similar in design, but the functions and functionality of each model will differ. It is important to know how to use your BC properly and make a backup plan in case of malfunction.

Pneumatic valves allow for the control of depth.

Pneumatic valves are the heart of most industrial processes. They use a force balance principle to control fluid flow. A pneumatic valve is equipped with three ports: an exhaust, control signal output, or air supply. The control device is controlled by a lever arm. The flexible diaphragm on the arm changes the pressure depending on how an external sensor positions it. The left end of the lever arm lifts when the sensor's pressure is high and opens the supply valve. The increased pressure causes the controlled device to move.